5 axis machining

5 axis machining Specification

- Hardness

- Up to 60 HRC (Depending on material)

- Method

- Subtractive Manufacturing

- Coating

- Anodizing, Passivation, Black Oxide, Nickel Plating

- Shape

- Custom / Complex Geometries

- Machine Type

- 5 Axis Vertical/Horizontal CNC

- Accuracy

- 0.005 mm mm

- Weight

- Varies with Design GSM (gm/2)

- Cutting Speed

- Up to 10,000 mm/min Km/hr

- Spindle Speed

- Up to 24,000 RPM Km/hr

- Load Capacity

- Application Dependent Gram (g)

- Size

- Custom, up to 500mm x 500mm x 300mm

- Material

- Aluminum, Stainless Steel, Brass, Titanium

- CNC

- Yes

- Tolerance

- 0.005 mm Millimeter (mm)

- Use

- Precision Engineering Parts

- Application

- Automotive, Aerospace, Medical, Electronics

- Usage & Applications

- Prototyping, Small Batch & Large Volume Production

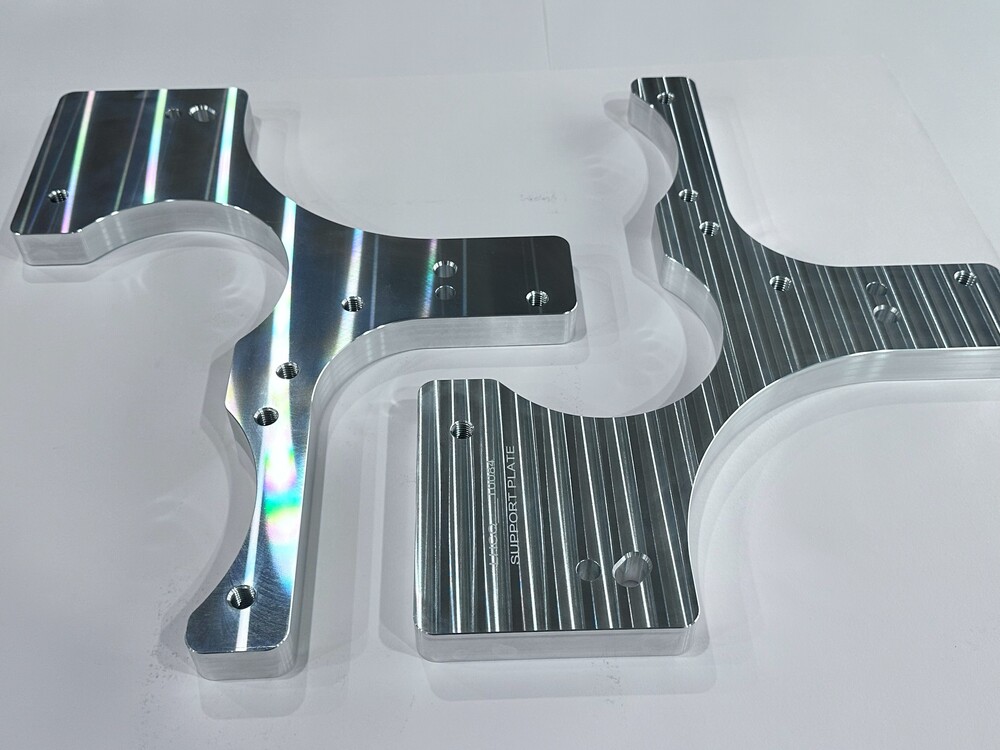

About 5 axis machining

With dexterous team of professionals and vast industry experience, we have been able to manufacture, export and supply a qualitative range of Precision Axis Machined Components include 5 Axis CNC Machined Components. Under the proper supervision of our technical experts, these components are efficiently manufactured in accordance with predefined industry standards using optimal quality raw metal alloy. Offered components are well suited for varied industrial machines. 5 Axis CNC Machined Components size Dia. 850mm x 550mm Height.

Major Features:

- High precision machining using glass scales.

- Unmanned inspection on state of art CMM

Unmatched Precision for Complex Needs

Designed for applications where accuracy is paramount, our 5 Axis CNC machining achieves tolerances as tight as 0.005 mm. This level of precision makes the components suitable for intricate engineering tasks in various sectors including aerospace and medical devices.

Advanced Surface Finishes

Multiple finishing options such as anodizing, sandblasting, and polishing offer a professional appearance and enhanced durability. Coating choices like passivation and black oxide further extend component longevity and resistance to environmental effects.

Customization and Versatility

Whether you require unique shapes or specific sizes up to 500mm x 500mm x 300mm, our CNC machining solution adapts to your design needs. The process supports complex geometries and a range of hardness levels, catering to both prototyping and large-scale production.

FAQs of 5 Axis CNC Machined Components:

Q: How does the 5 Axis CNC machining process benefit my project over conventional methods?

A: 5 Axis CNC machining provides superior flexibility and precision, allowing for the creation of complex shapes and geometries in a single setup. This reduces production time, enhances accuracy, and ensures consistent quality across prototypes, small batches, and large volume production.Q: What materials can be used for these machined components?

A: We offer 5 Axis CNC machining in materials such as aluminum, stainless steel, brass, and titanium. Each is selected based on your applications requirementsstrength, hardness, corrosion resistance, or conductivity.Q: What surface finishes and coatings are available for these components?

A: Available finishes include anodized, sandblasted, and polished surfaces. Coating options include anodizing, passivation, black oxide, and nickel plating. These treatments boost durability, appearance, and environmental protection.Q: Where are these CNC machined components manufactured and supplied from?

A: Our components are manufactured, exported, and supplied from India, ensuring high-quality production standards and reliable service to domestic and international clients.Q: When should I choose 5 Axis CNC machined components for my application?

A: Choose 5 Axis CNC machined components when your application requires high tolerance, intricate designs, or multiple axes of machiningespecially in automotive, aerospace, medical, and electronics industries.Q: What is the maximum size and load capacity for these components?

A: Custom components can be manufactured up to 500mm x 500mm x 300mm. Load capacity depends on the specific design, material used, and application requirements.Q: How accurate are the CNC machined components produced?

A: Our 5 Axis CNC machining achieves high accuracy, maintaining tolerances as precise as 0.005 mm to meet the stringent demands of precision engineering applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 5 Axis Machining Category

Inconel Machining Services

Weight : Lightweight to heavy depending on design

Usage & Applications : Aerospace automotive marine etc.

Hardness : High

Thread Type : Other, Customizable

Shape : Custom shapes (e.g. circular shown)

Method : Machining

Send Inquiry

Send Inquiry